Weaving the fabric of open innovation

Recoil pads — they are tough, durable and engineered to absorb the impact of thousands of shots when firing from a rifle. To most people, this is the furthest thing associated with the intricate craftsmanship of a bra.

But the innovators at MAS Holdings saw more in the recoil pad than its intended function of protecting soldiers from shoulder bruises. They recognized the untapped potential of a highly engineered material.

What if it could be used to shield and support other sensitive parts of the body?

“We make a lot of foam cups for bras. We were able to find this soft impact foam that was being used in the gun industry and modify it to drastically improve support in our bra cups,” explained Nathan Sivagananathan, Chief Growth Officer at MAS Holdings.

More than a million bras have been manufactured using this new material to date after the idea was conceived two years ago by MAS Holdings.

The company is no stranger to making apparel, having produced underwear, sportswear, and swimwear for some of the world’s biggest international brands such as Nike, Lululemon, Triumph and Victoria’s Secret.

It recorded revenues of more than US$1.7 billion (€1.49 billion) in 2017 and currently employs 99,000 staff across 16 countries. In a year, the company produces up to 30 million bras, 120 million pairs of knickers, 100 million pieces of sports clothing, 40 million outerwear garments, 15 million swimsuits, and more than a billion meters of fabric, lace and elastic.

While size and scale matter in an extremely competitive textile industry, it is an emphasis on innovation that differentiates the company from the rest.

Back in 2005, MAS Holdings lost half of its orders to a Chinese manufacturer. This spurred the company to begin investing in research and development (R&D).

Fast forward eight years later, MAS Holdings launched an innovation arm called Twinery to come up with novel solutions to real-world problems through partnerships with external companies, organizations, start-ups and individuals, and to roll these solutions out commercially.

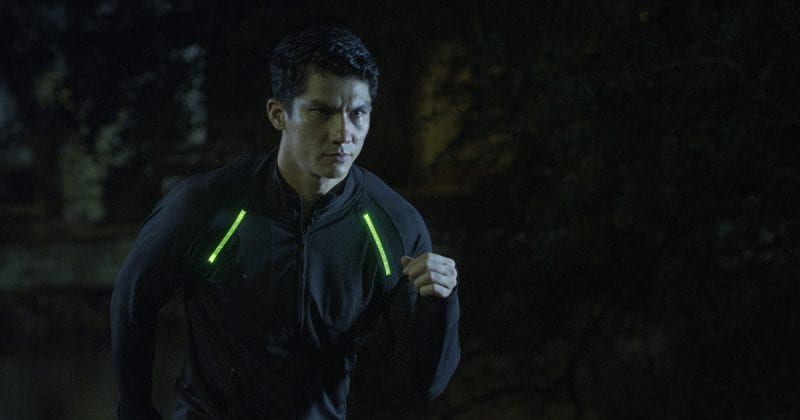

With Twinery, the company has developed some of the most innovative products in the industry, from pee-proof underwear for women with incontinence, to illuminated running jackets that let you be seen from 500m away, and inner-wear that helps menopausal women regulate hot flushes.

The innovation roadmap

Twinery’s objective is simple: to ignite, elevate, and accelerate the process of innovation in the company, shared Sivagananathan.

Over the past five years, the Twinery team has been looking beyond its internal R&D department, finding solutions to everyday problems from its network of partners through an open challenge program.

The program has since been launched with an online platform that runs open calls for innovative solutions to issues identified, such as enhancing the feel of lower grade cotton and making leak-free swimwear for women on their period.

“We built the technical platform and launched it this year. Before this, we were reaching out directly to our partners and sending out emails to hundreds of people. But now, we have brought it into a system where we are able to use more artificial intelligence to understand the problems that we are trying to solve,” he said.

The company took on such an approach because product cycles are shrinking, and the time taken to market a product is increasingly crucial. Having an open platform for innovation shortcuts the process and accelerates the company’s ability to commercialize products quickly.

“Everything is about speed to market now. R&D takes three to five years before the products get out to the market. With the open challenge, we are able to take products to market in 12 months,” said Sivagananathan.

“We believe that not everything has to be built in-house.”

Twinery’s approach to innovation has delivered: the apparel manufacturer has accepted around 40 tech solutions from individuals, labs, and companies around the world, and has brought 20 to market.

“We work with a wide array of people in the ecosystem — in the wearable technology, feminine hygiene, as well as the textile space. We have been able to work around these three areas and build a strong network of people and companies.”

MAS Holdings’ approach is similar to how other big companies are looking at innovation. Many have set up incubation centers both for their employees and in partnership with external start-ups.

For instance, DHL looks back to its own employees for ideas that have the potential to disrupt and reshape the logistics industry. Its Start-up Lab incubator program gives employees an opportunity to pitch and execute these very ideas.

This has helped to generate new models of business, carve out new customer segments, and encourage the adoption of technologies and innovation within the company.

Developing new lines of businesses

For MAS Holdings, the future of apparel lies in technology — not just in terms of the materials that go into producing a t-shirt, but in the potential uses of those pieces of clothing.

“We have two types of businesses that we develop technologies for — one is for our existing core business, which is apparel manufacturing. Our ‘Futureworks’ unit also develops new adjacent businesses opportunities that leverage our knowledge in the existing industry,” Sivagananathan shared.

MAS Holdings envisions partnering with DHL to develop products that help the employees of the logistics company — such as through a smart heating jacket that regulates temperature according to the wearers’ needs, eliminating the need for bulky layers.

It sees a future where industry is made safer through smart apparel kitted with bio-mechanical sensors that help people lift and carry products without hurting themselves, or which monitor drivers’ vital signs to catch fatigue and prevent accidents.

“We believe that the future is about using innovation as a tool to disrupt our own business. Globally, a lot of ideas that come into the market are through a consumer viewpoint. We’ll continue to use these inputs, along with open innovation, to bring new ideas to market and to build new businesses,” added Sivagananathan.

MORE FROM THIS COLLECTION

English

English