In the cold seat: choosing between reefer containers and alternatives

The increased use of refrigerated shipping containers – known in the logistics industry as reefer containers – has revolutionized perishable goods transportation all around the world.

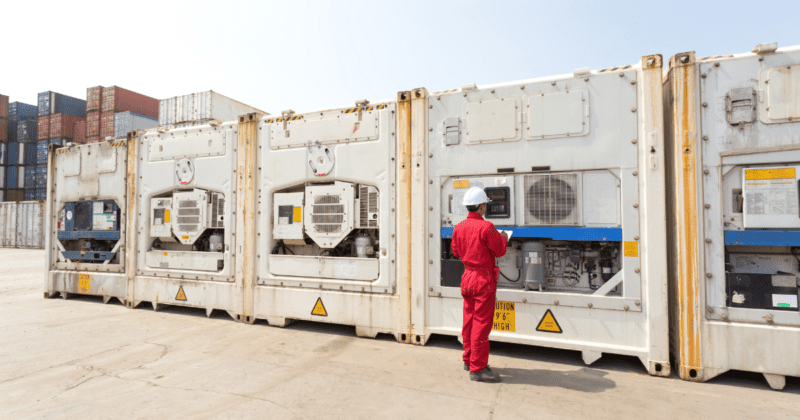

International trade expansion, an increased consumer focus on the safety and quality of food and beverages, and improvements in cold chain technologies have all contributed to the growth of the reefer container market in recent years. Reefer containers are specialized containers designed to transport perishable goods that require a controlled environment with fixed temperature and humidity to preserve freshness, quality, and safety. It typically features a built-in refrigeration unit, insulation, air circulation, monitoring and control systems, and an external power supply to operate the refrigeration unit. It fits compatibly in various modes of transport, including ships, trucks, and trains.

Reefer containers are used widely across industries that involve cold chain logistics, from your typical daily shopping basket of perishable food and beverages, including fruit, vegetables, meat, dairy products, seafood, juice, and wine). They are also used for pharmaceuticals such as blood products and medical supplies, as well as chemicals and industrial products, flowers and plants, and even temperature-sensitive items such as cosmetics and electronics.

They are a common solution across the cold chain logistics industry, but are reefer containers the best solution for transporting your perishable goods?

The pros and cons of reefer containers

Many carriers consider reefer containers an ideal solution due to their various attributes. For example, they help extend the shelf life of perishable goods over extended periods and distances. They also help carriers improve product safety and achieve regulatory compliance.

However, reefer containers come with a few crucial caveats. First of all, apart from being expensive to operate and maintain, reefer containers have limited temperature flexibility (for different products in a single container) and overall capacity. They also depend on external power sources and require up-to-date infrastructure at ports, terminals, and other transport facilities to function, making them vulnerable to technology disruptions and mechanical breakdowns.

Alternatives to reefer containers

Before choosing to use reefer containers for perishable goods transportation, carriers should first consider the nature of their shipments. Not all shipments require the full package that the reefer container offers.

Shippers can achieve the same effectiveness using cheaper alternatives with less extensive capabilities for products with a longer shelf-life or that do not require extremely low temperatures. These include insulated (but not refrigerated) containers, which could be more suitable.

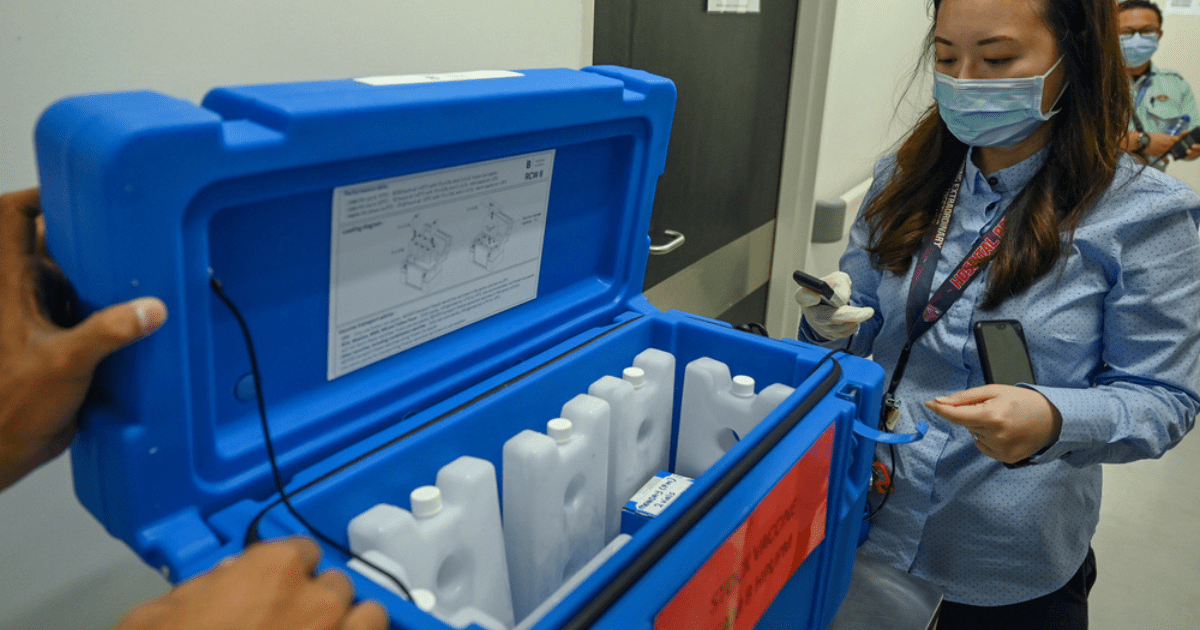

These shipments are lower-maintenance, and in place of reefer containers, carriers can use cooling agents (such as dry ice or gel packs) or specialized thermal packaging to transport small quantities of perishable goods over short distances in regular containers. Reefer trucks or vans might be another suitable option for short-distance transportation.

Perishables retailers have also opted for modified atmosphere packaging – which involves adjusting gas composition to alter the atmosphere around perishable goods in traditional containers. By changing the packaging's oxygen and carbon dioxide content, retailers slow down the respiration rate of fruits and vegetables. This inhibits the growth and reproduction of microorganisms and the generation of ethylene, prolonging the shelf life of the packaged food product. This method can be cost-effective when combined with other cold chain alternatives, such as gel packs and iceboxes.

For certain product types, ventilated containers with airflow mechanisms can help regulate the temperature and humidity. In some cases, sea ice and air vents can be used in maritime transport to provide natural refrigeration, especially for products that can tolerate slightly higher temperatures.

To expedite the transportation process, carriers often pair these alternatives in cool-packaging methods with temperature-controlled air freight services, to get their perishables shipped overseas faster. Cutting down on transit time gives shippers more leeway to opt for cheaper alternatives to reefer shipping for less temperature-sensitive products.

Are reefer containers right for your business?

Still, reefer containers serve specific functions in the cold chain that few alternatives can match. It offers shippers complete control over the product’s storage environment during transit, from fixed temperatures and humidity levels, allowing carriers to comply with stringent regulatory standards and guarantee the safety and quality of perishable goods during transit.

Reefer containers have become essential in the rapid development of global cold chain logistics. The development of a seamless cold chain optimizes the supply chain process, reducing transit times and minimizing wastage, which helps carriers reduce costs and improve profitability.

By enabling the transportation of perishable goods across longer distances, reefer shipping also allows carriers and producers to expand to markets in further regions, hence opening up new revenue streams.

And as international reefer container shipping grows more prominent, perishables producers in the Asia Pacific are not only counting on reefer logistics as an integral part of their cold chain processes. They are leveraging the advantages of reefer logistics to give them an edge in the market. For instance, Japanese seafood exporters are equipping reefer containers to help mitigate inconsistent temperature control during maritime transport. Similarly, by suspending avocados in atmospherically controlled reefer containers, Australian avocado producers are managing the supply of the fruit entering markets at a consistent price worldwide.

As busy ports such as Shanghai, Singapore, Hong Kong, Guangzhou, and Shenzhen continue to serve as vital transshipment points for perishables moving between Asia and other regions of the world, analysts are forecasting that Asia Pacific will continue to dominate the reefer container market until at least 2030.

Reefer containers remain an indispensable solution for sensitive or high-value long-distance perishables shipments. And with future improvements in technology and infrastructure, reefer containers will likely evolve into an even more useful component of carriers’ perishable goods logistics strategies. Shippers will always have to make strategic choices between reefer containers and alternatives by carefully balancing the priorities of precision and pragmatism.

ALSO WORTH READING

English

English