AI-driven big data analytics: the next big thing in supply chain management

Is big data analytics in supply chain management about to have another big breakthrough? Logistics experts are discovering the value of AI-driven, real-time analytics to achieve the visibility needed for more robust and resilient supply chains. And business leaders are discovering the value of state-of-the-art supply chain management to deal with disruption and achieve strategic goals.

Past, present, future

Knowing the past is critical to understanding the present and steering the future. What is true in life is true in business, and data is the raw material that makes such insight possible. Supply chain professionals have grasped the importance of data for decades, as evidenced by the industry’s embrace of the Internet of Things (IoT) through sensors, smart tags, and such. The potential treasure trove of data generated annually from IoT devices, augmented by user-generated content, is predicted to balloon to some 181 trillion gigabytes by 2025.

Processing capacities have not kept up with this deluge of data, however. And the task grows even more daunting given the unstructured nature of much of this data, including audio and video files and social media feeds – vastly transcending anything that can be managed in spreadsheets.

Enter AI-driven big data analytics – the process of deploying smart tech such as automation and artificial intelligence (AI) to reveal patterns in the past, highlight real-time changes in the present, and reliably predict trends in the future.

Big data gets bigger, growth gets faster

Big data gets bigger, growth gets faster

Volume of data created, captured, copied, and consumed worldwide from 2010 to 2020, with forecasts for 2021 to 2025 (in gigabytes)

2010: 2 TRILLION

2020: 64 TRILLION

2025: 181 TRILLION

Source: Statista

There is no end to the trend in big data analytics

We have been monitoring the trend of big data analytics in logistics and supply chains for years. The power of data-driven insights is transforming many industries, including logistics. So it was no surprise to see it again in the DHL Logistics Trend Radar 6.0 – the 2022 result of our ongoing trend research. We continue to see big data analytics as a high-impact, near-term trend.

Big data analytics does no transform the supply chain physically, but it delivers greater visibility and a better foundation for sound decision-making toward strategic optimizations along supply chain segments. The result is substantially improved service levels, ranging from more efficient pallet storage in warehouses to better customer case handling. And the logistics industry already has a big head start here. Many industry leaders have begun harnessing big data to drive strategic decisions, and soon this trend will simply be standard business practice in logistics and supply chain management.

"We are seeing businesses transform logistics from a quiet, backend operation to a strategic asset and value driver," said Katja Busch, Chief Commercial Officer of DHL and Head of DHL Customer Solutions and Innovation

Four types of big data analytics

To approach the daunting topic of AI-driven, real-time analytics of big data, with its potential to transform today’s supply chains, let us break it down into its four main types: descriptive, diagnostic, predictive, and prescriptive.

Descriptive analytics is about understanding the status quo and describing what is happening, while diagnostic analytics asks why it happens. Predictive analytics forecasts what will likely happen in the future, while prescriptive analytics taps into historical and situational data to recommend strategic optimizations to be implemented.

Types of data analytics

Types of data analytics

DESCRIPTIVE

What happened?

A careful analysis of big data in logistics can help you understand your supply chain performance.

DIAGNOSTIC

Why did it happen?

Big data unlocks the secrets of what went right or wrong – and why.

PREDICTIVE

What is likely to happen next?

Your historical data holds valuable clues that can yield predictions about future performance.

PRESCRIPTIVE

What should we do about it?

AI can mine big data to generate “lessons learned” for strategies going forward.

Supply chain analytics in action

As the potential to harvest big data grows, so does the opportunity to harness it. But what does that look like in today's supply chains?

Let us look at some real-world use cases for leveraging the power of big data analytics:

Inventory and asset optimization

Want to improve efficiency in warehouses and hubs? Big data analytics delivers the supply chain visibility needed to optimize how inventory is stored and moved through facilities and how assets are utilized and maintained.

- Descriptive: Utilize sensor data to reveal inventory levels, available shelf space, and the location and status of warehouse assets.

- Diagnostic: Show links between inventory types and the breakdown of assets like conveyors or vehicles or between external events and inventory levels.

- Predictive: Fine-tune preventive maintenance intervals for assets and optimize inventory in anticipation of predictable seasonal fluctuations.

- Prescriptive: Mine historical data to optimize space allocation by stock-keeping unit (SKU) and prevent unnecessarily high or critically low inventory levels.

Transport and delivery optimization

Have a particularly challenging supply chain segment? Big data analytics can help you achieve cost-effective, on-time performance while ensuring your goods arrive in good condition.

- Descriptive: Use service-level data to obtain a real-time analysis of the status of transport vehicles or the condition of delivered goods.

- Diagnostic: Determine why persistent delays occur. For example: Are schedules out of sync with traffic patterns?

- Predictive: Examine various data sources to anticipate the risk of disruption along supply chain segments, even accounting for factors such as natural disasters and political violence.

- Prescriptive: Analyze past data for insights into optimal scheduling and fleet sizes to make the most of your capacities and achieve your best on-time performance.

Supplier risk and due diligence assessment

Want to bypass the tedious work of evaluating current or potential supplier and vendor partnerships? Big data analytics is the key to optimizing risk-and-resilience due diligence.

- Descriptive: Use data from sensors and other sources to evaluate supplier performance (timely delivery, quality, etc.) in real-time.

- Diagnostic: Apply this data to discern patterns and understand what makes some suppliers better than others.

- Predictive: Support vendor selection by comparing supply chain criteria to automatically forecast each vendor’s likelihood of meeting your needs in the event of a disruption.

- Prescriptive: Analyze vendor performance to grade and classify existing and potential partners and make purchasing decisions.

Customer management

Want to strengthen brand loyalty? Big data analytics can help you improve your customer experience and journey.

- Descriptive: Group B2B and B2C customers by category using attributes like industry, age, region, order size, and needs – then display the data in an intuitive dashboard to better understand your customer base and who may be affected by supply chain changes.

- Diagnostic: Demystify customer churn or preferences driven by price, convenience, or other variables.

- Predictive: Generate customer-facing use cases, and use demand forecasting to alleviate supply chain bottlenecks or underutilization of facilities and fleets.

- Prescriptive: Process historical data to determine price elasticity and ensure a better price point within customer expectations. Look at past orders to optimize the current workforce while protecting service levels. Mine consumer data to enable more personalized customer journeys and boost customer retention.

"Big data harbors a treasure trove for business insights into all parts of the supply chain for a portfolio of purposes, e.g., efficiency, resilience, and sustainability," said Klaus Dohrmann, VP Head of Innovation and Trend Research, DHL Customer Solutions & Innovation

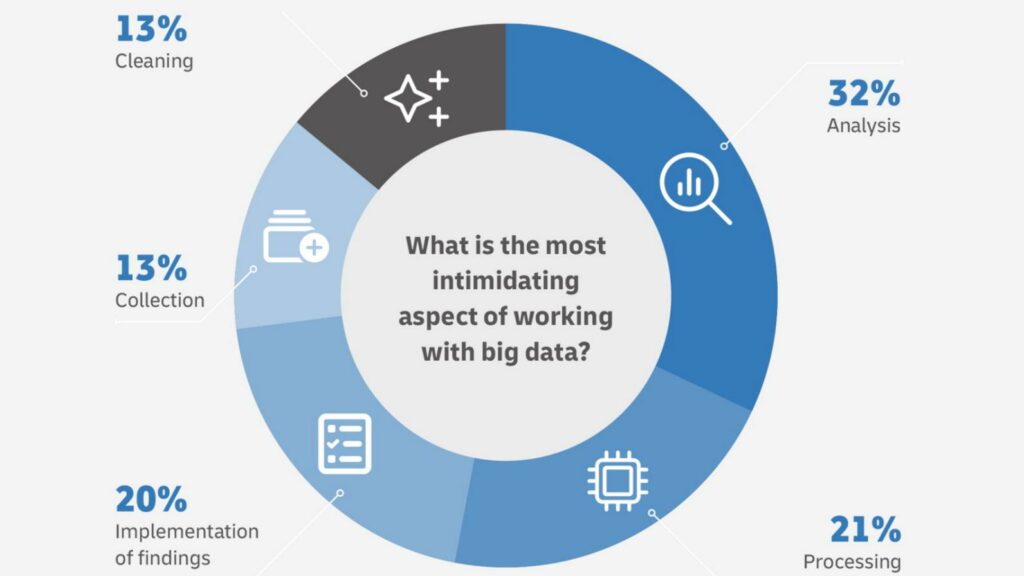

The challenges of big data analytics

Most, if not all, logistics leaders today are harnessing big data analytics to drive strategic decisions. But even those who have taken the plunge admit there are many challenges. The three most-cited fear factors are “analysis,” “processing,” and “implementation of findings.”

We agree that working with big data analytics can be intimidating, which is why data analysts are essential members of our supply chain management teams. From the logistics perspective, we see the following three immediate challenges:

Identifying the target

Big data analytics needs data – so before embarking on a big data analytics journey, you must identify which data types are valuable to your organization, and then build the appropriate data-collecting networks of sensors and other technologies.

Cleaning it up

Most data, especially from the internet, is unstructured and needs to be “cleaned” and filtered to achieve the quality required for meaningful analysis. Automating this process takes time, money, and talent.

Protecting your asset

Data is a valuable asset. Protecting it from bad actors requires a robust cybersecurity infrastructure.

What is the final (big data) analysis?

Visibility is the key to building resilient supply chains. With today’s AI-driven analytics capabilities, big data is poised to improve supply chain performance and boost supply chain resilience with virtually no changes to existing supply chain infrastructure. Early adopters have continually integrated the latest advances for ever-better descriptive, diagnostic, predictive, and prescriptive insights. Sooner rather than later, these big data analytics techniques will be considered standard practice in supply chain management and expected by customers across all industry sectors.

This story was first published on DHL Delivered and was republished with permission.

ALSO WORTH READING

English

English