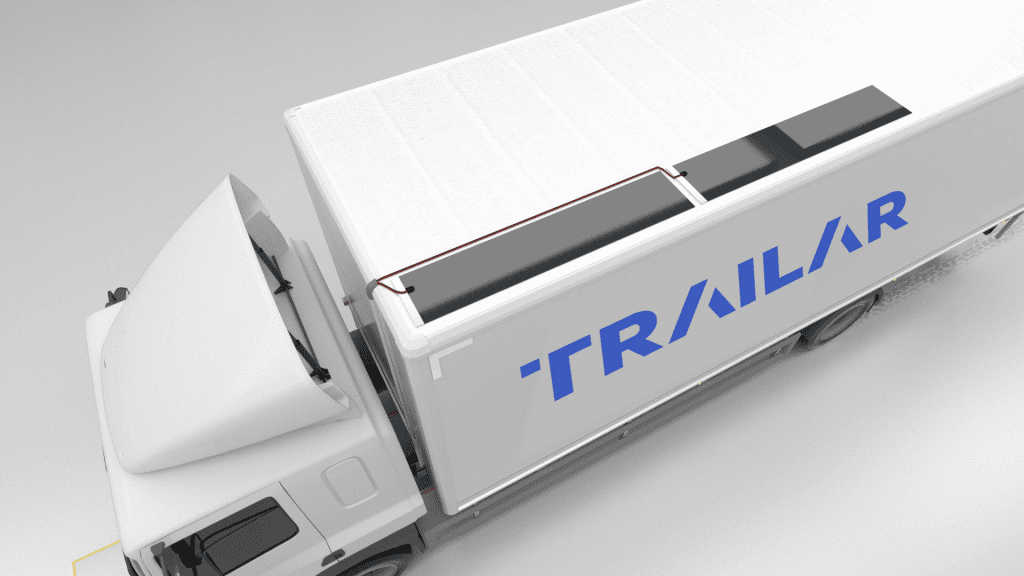

TRAILAR: 5% fuel savings, powered by solar innovation

It all began during the Management Development program “Business Transformation Academy” in the United Kingdom in 2015.

Alongside dozens of other colleagues, Aaron Thomas and Denny Hulme were paired up and tasked with thinking of products that could potentially disrupt the transportation industry in the UK.

Instead of riding the wave of digital technology applications, however, they opted for a more hands-on approach.

“We thought about the rising popularity of solar power around the UK and solar fields springing up all around us and we wondered if there was a way to use solar energy to power up vehicles,” recalled Hulme.

Armed with that very question, they set off in search of answers which could potentially change the game for the logistics industry.

Enter the dragon

In no time, the duo came up with an idea: to generate extra energy for trucks through solar panels on their roofs. What followed were nine months of hard work to turn their idea into a feasible concept.

Thomas’ and Hulme’s efforts eventually bore fruit, as they realized that the key to making their idea work was to use solar energy as an extra power source for the vehicle battery.

Traditionally, the engine bears the full burden of charging the batteries, which requires the burning of diesel.

TRAILAR’s solar-powered solution provides an alternative, cleaner solution. It applies ultra-thin, flexible solar panels to a vehicle’s roof space and connects them to the vehicle battery or additional on-board batteries.

Harvested solar energy is then used to power a tail lift and all ancillary equipment such as air conditioning.

Buoyed by the validation of their idea, Thomas and Hulme reached out to the leading UK trailer manufacturer Don-Bur, and a solar panel provider in Silicon Valley to produce a first prototype they could present to their management team.

“We were given around nine months to develop a prototype for our project. After that time period, we were to present to the CEO of DHL SC UK&I. It felt a bit like being a contester in the ‘Dragon’s Den’,” explained Thomas, referencing the British reality television show where aspiring entrepreneurs pitch their business ideas to investors.

Thomas and Hulme delivered on the challenge. Their TRAILAR prototype promised 5 percent less diesel consumption and 5.1 percent less carbon emissions.

Incubating an idea

One year later, Thomas and Hulme applied for Deutsche Post DHL Group (DPDHL) Group’s Start-up Lab incubator program, which provides selected teams with resources such as coaching, funding, and mentoring to validate their ideas in a start-up-like environment.

Up against tough competition, TRAILAR was eventually shortlisted out of 152 teams that applied for the initial Start-up Lab batch in early 2017.

“We went on further and presented it to the Corporate Board, which selected us as one of only eight teams,” recounted Thomas.

“As a key contributor to our GoGreen program and to reducing the Group’s carbon emissions, TRAILAR is a great proof point of what we aim to achieve with Start-up Lab: Give the many great minds in our company an opportunity to put their ideas into action,” said Thomas Ogilvie, DPDHL Group board member for Human Resources and Corporate Incubations.

“Instead of waiting to be disrupted by others, Start-up Lab lets us drive innovative ideas ourselves and create an edge against our competitors,” added Ogilvie.

“Looking back, it has been a roller coaster ride, seeing how an idea from two and a half years ago has now turned into reality,” said Thomas about their path toward getting TRAILAR on the road.

A bright future

Since TRAILAR was accepted into the Start-up Lab, it has been on a roll.

In mid-2017, the company successfully trialed the technology on 30 DHL rigid vehicles and trailers in the UK.

“The plan is for the technology to be deployed on 150 more vehicles in the country by the end of 2018,” said Hulme.

The TRAILAR team has also started cooperation with DHL’s SmarTrucking initiative in India, where six trucks will be outfitted with its technology.

If these trials work out, TRAILAR could soon be rolled out on tens of thousands of vehicles across DHL’s operations.

In September this year, TRAILAR had their first appearance on the external market outside of the UK at the IAA Commercial Vehicles Show in Hanover/Germany, one of the world's leading trade shows for transport, logistics and mobility.

“From major truck and trailer manufacturers and leasing companies to small and medium-sized transport businesses, the interest in TRAILAR was astounding,” said Hulme. “It certainly motivates us to do our homework between now and the summer of 2019 — that is when we want to start fitting the vehicles of our external customers.”

And TRAILAR’s ambition does not stop there. The team, which has grown to six people in the meantime, is already exploring additional use cases for their solution.

“We’re currently developing our first refrigerated truck prototype. We hope to get it out on the roads by the end of this year,” shared Thomas.

The team is well aware of their competition, especially as other companies have also made investments in the development of partially solar-powered vehicles.

Thomas, however, believes that TRAILAR has an edge.

“To this day, we have already invested three years in research and development, which gives us a firm head start. We can also draw from our year-long experience in logistics and transport operations. This lets us fully understand both the technical requirements of the vehicles and what our customers need to make TRAILAR work for them,” added Thomas.

With governments determined to phase out fossil-fueled vehicles progressively and more global businesses committing to the green movement, the market for such vehicles will only continue to grow — a sign that the best is yet to come for TRAILAR.

English

English