Yield Management

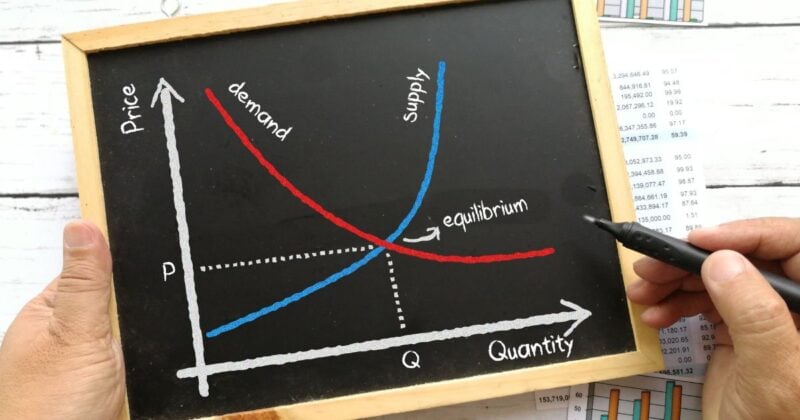

In the logistics space, yield management involves strategic control of inventory that dynamically adjusts resources and prices based on demand and supply factors. This approach is commonly used in industries where resources are limited and have a short shelf life. Leveraging data analytics, businesses draw from existing data, market trends, and consumer behavior insights to predict future demand.

Key components of yield management include:

Dynamic Pricing: Prices are adjusted in real time based on current market conditions, competitor pricing, and remaining inventory. For example, when demand is high, higher rates are applied for last-minute bookings of limited space across logistics assets, such as air and ocean freight, trucks, and warehouses. On the other hand, discounts are offered for early bookings or off-peak times.

Market Segmentation: Identifying different customer segments with varying willingness to pay. Based on purchasing behavior and preferences, logistics firms can adjust their pricing strategy to fit each customer segment.

Demand Forecasting: Analyzing historical data to predict future demand patterns. For instance, a logistics company may analyze past travel patterns to anticipate peak shipping seasons, allowing it to adjust prices accordingly. During high-demand periods, prices can be increased, while during off-peak times, discounts may be offered to stimulate demand.

Resource Optimization: Managing limited resources to optimize revenue. This ensures that every unit of capacity, such as truckload, warehouse pallet position, or container space, is utilized as profitably as possible to minimize empty runs and underused resources.

By implementing these strategies, organizations can significantly enhance their revenue potential while maintaining a competitive edge in the market.

English

English